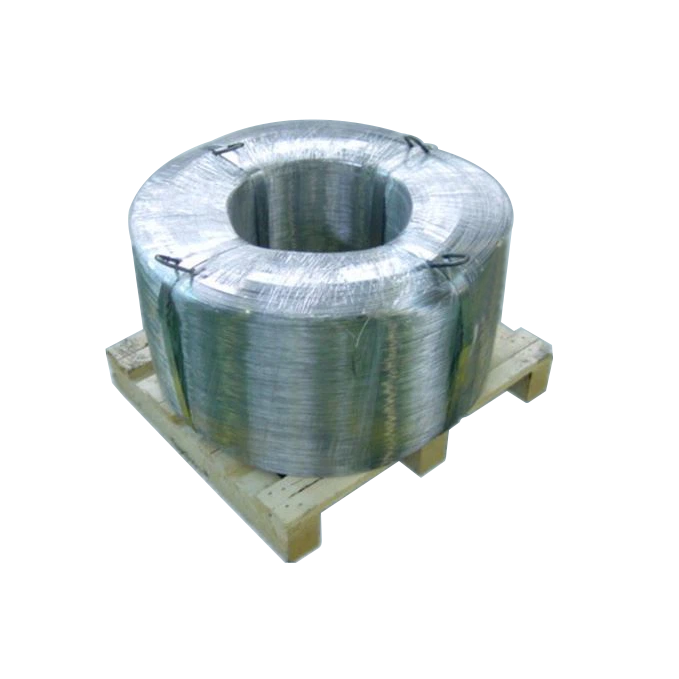

Galvanized Iron Wire For Car Seats Or Door Locks

Production Process

It is made of high quality low carbon steel coils, galvanized iron wire is divided into hot galvanized wire and cold galvanized wire (electro galvanized wire) is made of high quality low carbon steel, through the process of drawing, pickling and rust removal, high temperature annealing, hot galvanizing, cooling and other processes.

Galvanized iron wire has good toughness and elasticity, and the maximum amount of zinc coating can reach 300g/m². It has the characteristics of thick galvanized layer and strong corrosion resistance.

Galvanized Wire is made to BS and ASTM standard. The metallic zinc coatings applied by the galvanizing process are an effective way of combating corrosion in steel. Galvanized wire for general manufacturing purposes is available in a standard galvanized coating or a heavy galvanized coating.

Standard galvanized coatings are smoother, however less corrosion resistant than heavy galvanized coatings and are often used in normal wire working applications. Some typical end users include cages, bucket handles, coat hangers and baskets.

Heavy galvanized coatings are used in conditions where atmospheric corrosion is severe. End users include crop support wires where chemicals are used, pool fencing or chain mesh in coastal areas.

The galvanized iron wire for car seat or door locker is widely used in DAS AUTO, HONDA, TOYOTA, BWM, BENS etc

Additional Info

Diameter Range: Std. Gal. 0.15-8.00 mm

Diameter Range: Heavy Gal 0.90-8.00 mm

Surface Finish: Standard & Heavy Galvanized

Galvanised Wire Working Specifications

Given that galvanized wire is classified according to the amount of zinc coating, the following table outlines the difference between standard, heavy galvanized and extra-high galvanized wire.

| Nominal Diameter | Minimum Coating Mass (g/m2) | ||

| Standard Galv. | Heavy Galv. | Extra-highGalv. | |

| over 0.15mm up to and incl. 0.50mm | 15 | 30 | |

| over 0.5mm up to and incl. 0.75mm | 30 | 130 | |

| over 0.75mm up to and incl. 0.85mm | 25 | 130 | |

| over 0.85mm up to and incl. 0.95mm | 25 | 140 | |

| over 0.95mm up to and incl. 1.06mm | 25 | 150 | |

| over 1.06mm up to and incl. 1.18mm | 25 | 160 | |

| over 1.18mm up to and incl. 1.32mm | 30 | 170 | |

| over 1.32mm up to and incl. 1.55mm | 30 | 185 | |

| over 1.55mm up to and incl. 1.80mm | 35 | 200 | 480 |

| over 1.80mm up to and incl. 2.24mm | 35 | 215 | 485 |

| over 2.24mm up to and incl. 2.72mm | 40 | 230 | 490 |

| over 2.72mm up to and incl. 3.15mm | 45 | 240 | 500 |

| over 3.15mm up to and incl. 3.55mm | 50 | 250 | 520 |

| over 3.55mm up to and incl. 4.25mm | 60 | 260 | 530 |

| over 4.25mm up to and incl. 5.00mm | 70 | 275 | 550 |

| over 5.00mm up to and incl. 8.00mm | 80 | 290 | 590 |

Diameter Properties

Standard Galvanized Wire is manufactured to comply with the following diameter tolerances:

Heavy Galvanized Wire is manufactured to comply with the following diameter tolerances:

| Nominal Wire Diameter | Tolerance (mm) |

| over 0.80mm up to and incl. 1.60mm | +/-0.04 |

| over 1.60mm up to and incl. 2.50mm | +/-0.04 |

| over 2.50mm up to and incl. 4.00mm | +/-0.04 |

| over 4.00mm up to and incl. 5.00mm | +/-0.05 |

| over 5.00mm up to and incl. 6.00mm | +/-0.05 |

| over 6.00mm up to and incl. 10.68mm | +/-0.05 |

Tensile Strength (Mpa)

The tensile strength is defined as the maximum load achieved in the tensile test, divided by the cross-sectional area of the wire test piece. Galvanized Wire is produced using soft, medium and hard grade wires. The following table specifies the tensile range according to the grade:

| Grade | Tensile Strength (Mpa) |

| Galvanised - Soft Quality | 380/550 |

| Galvanised - Medium Quality | 500/625 |

| Galvanised - Hard Quality | 625/850 |

Please note that the sizes mentioned above are indicative only and do not specify the size range available from my products range.

Steel Chemistry

A combination of steel grades is used and heat treatment processes to manufacture soft, medium and hard tensile grades. The table below is indicative only of steel chemistries used.

| Tensile Grade | % Carbon | % Phosphorus | % Manganese | % Silicon | % Sulphur |

| Soft | 0.05 max | 0.03 max | 0.05 max | 0.12-0.18 | 0.03 max |

| Medium | 0.15-0.19 | 0.03 max | 0.70-0.90 | 0.14-0.24 | 0.03 max |

| Hard | 0.04-0.07 | 0.03 max | 0.40-0.60 | 0.12-0.22 | 0.03 max |

Quality Control:

We use total quality control system. Every pieces of the raw material; semi-finished products and finished products are tested and recorded in file. The tracking record is used from final products to the very first beginning raw material steel factories.

Third Part like SGS is available for test control before shipment.

Every detail can stand the test

High quality raw materials

Strict selection of carben steel,strict control of the production process,good capacity.

Good toughness

The product has good toughness,strong plasticity and is not easy to break.

Galvanizing process

The coating is uniform,the adhesion is strong,it is not easy to rust,and it is used in many scenes.

Various specifications

A variety of sizes and specifications to meet different needs.

Safety operating procedures

1. Clear all tools and piles on the work site and equipment that hinder activities.

2. When pickling, put the wire into the tank slowly to prevent the acid from splashing on your body. Acid must be poured slowly into the water when adding acid, and it is forbidden to pour water into the acid to prevent acid from splashing out and injuring people. Wear protective glasses when working.

3、Handle wire and other items, forbidden to push and hit.

4. Wire reels should be placed lightly, stacked firmly and neatly, not higher than 5 reels.

5. Prohibit direct human skin contact with acid and alkali liquid.

Applications

The products are widely used in various fields such as construction, handicrafts, preparation of wire mesh, making galvanized hooked wire mesh, plastering wall mesh, highway fence, product packaging and daily civilian use.

About Us

Our Company mainly specializes in importing and exporting metal material and metal products, and we also do transit trade, domestic trade and agent operation. Our products have been sold to Europe, America, New Zealand, Japan, South Korea, Southeast Asia, the Middle East, Africa and Hong Kong. We have distributors at home and abroad. "High quality, reputation and good service" is our management concept. Sincerely cooperate with friends all over the world for the mutual development.