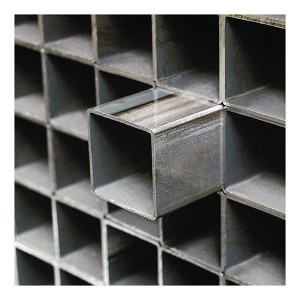

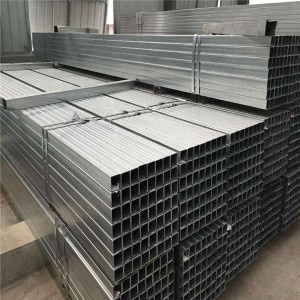

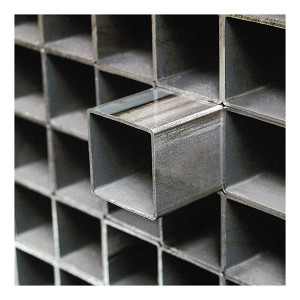

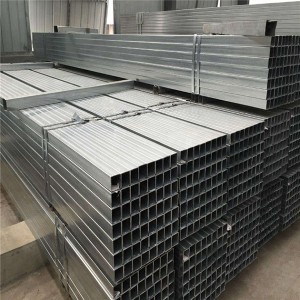

1. The hollow section must be made on a special inlet assembly line to ensure the accuracy of the air duct fabrication and the airtightness of the square tube.

2. The blanking of Rectangle Steel Tube fittings should be fully automated on imported special machines using computer software, and the automatic plasma cutting process should be completed on imported sheet metal special plasma cutting machines.

3. The bite connection of the Rectangle Steel Tube should adopt the imported automatic bite device for the bite process.

4. The connection between the Rectangle Steel Tube body and the plug-in flange should adopt the rivet-free connection process, and the imported equipment should be used for the rivet-free connection process.

5. The connection flange of the Rectangle Steel Pipe should adopt the connecting plate flange and the plug-in flange connection process. When the length of the large side of the air duct is less than or equal to 2000mm, the connection form of the common plate flange should be used, and the length of the large side of the air duct should be greater than or equal to 2000mm. When the diameter is 2000mm and less than or equal to 2500mm, the connection form of plug-in flange should be adopted. The rectangular air duct should be mechanically pressed with reinforcing ribs, and the spacing between the reinforcing ribs should be about 300mm.