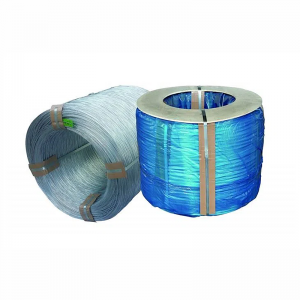

Hot Dip Zinc Alloy Wire

Zinc alloy wire is a popular material used in a variety of industries due to its unique properties and versatility. It is composed of a mixture of zinc and other metals, such as copper, aluminum, or magnesium, which enhances its strength and durability. The alloy is often used in manufacturing processes, construction, and even in jewelry making.

One of the most significant advantages of zinc alloy wire is its malleability. This property makes it easy to shape and bend into different forms without breaking or cracking. This quality also allows for the creation of intricate designs, making it a popular choice for jewelry makers. The alloy can be easily molded into different shapes, such as loops, spirals, and intricate patterns, making it a favorite among designers.

Galvanised Wire Working Specifications

Given that galvanized wire is classified according to the amount of zinc coating, the following table outlines the difference between standard, heavy galvanized and extra-high galvanized wire.

| Nominal Diameter | Minimum Coating Mass (g/m2) | ||

| Standard Galv. | Heavy Galv. | Extra-highGalv. | |

| over 1.80mm up to and incl. 2.24mm | 35 | 215 | 485 |

| over 2.24mm up to and incl. 2.72mm | 40 | 230 | 490 |

| over 2.72mm up to and incl. 3.15mm | 45 | 240 | 500 |

| over 3.15mm up to and incl. 3.55mm | 50 | 250 | 520 |

| over 3.55mm up to and incl. 4.25mm | 60 | 260 | 530 |

| over 4.25mm up to and incl. 5.00mm | 70 | 275 | 550 |

| over 5.00mm up to and incl. 8.00mm | 80 | 290 | 590 |

Diameter Properties

Standard Galvanized Wire is manufactured to comply with the following diameter tolerances:

| Nominal Wire Diameter | Tolerance (mm) |

| over 0.80mm up to and incl. 1.60mm | +/-0.03 |

| over 1.60mm up to and incl. 2.50mm | +/-0.03 |

| over 2.50mm up to and incl. 4.00mm | +/-0.03 |

| over 4.00mm up to and incl. 6.00mm | +/-0.04 |

| over 6.00mm up to and incl. 8.00mm | +/-0.04 |

Heavy Galvanized Wire is manufactured to comply with the following diameter tolerances:

| Nominal Wire Diameter | Tolerance (mm) |

| over 0.80mm up to and incl. 1.60mm | +/-0.04 |

| over 1.60mm up to and incl. 2.50mm | +/-0.04 |

| over 2.50mm up to and incl. 4.00mm | +/-0.04 |

| over 4.00mm up to and incl. 5.00mm | +/-0.05 |

| over 5.00mm up to and incl. 6.00mm | +/-0.05 |

| over 6.00mm up to and incl. 8.00mm | +/-0.05 |

Tensile Strength (Mpa)

The tensile strength is defined as the maximum load achieved in the tensile test, divided by the cross-sectional area of the wire test piece. Galvanized Wire is produced using soft, medium and hard grade wires. The following table specifies the tensile range according to the grade:

| Grade | Tensile Strength (Mpa) |

| Galvanised – Soft Quality | 380/550 |

| Galvanised – Medium Quality | 500/625 |

| Galvanised - Hard Quality | 625/850 |

Please note that the sizes mentioned above are indicative only and do not specify the size range available from my products range.

Steel Chemistry

A combination of steel grades is used and heat treatment processes to manufacture soft, medium and hard tensile grades. The table below is indicative only of steel chemistries used.

| Tensile Grade | % Carbon | % Phosphorus | % Manganese | % Silicon | % Sulphur |

| Soft | 0.05 max | 0.03 max | 0.05 max | 0.12-0.18 | 0.03 max |

| Medium | 0.15-0.19 | 0.03 max | 0.70-0.90 | 0.14-0.24 | 0.03 max |

| Hard | 0.04-0.07 | 0.03 max | 0.40-0.60 | 0.12-0.22 | 0.03 max |

Another benefit of hot dip wire is its strength. The addition of other metals to zinc improves its durability and tensile strength, making it suitable for applications that require a sturdy material. This strength makes it useful for creating components in the automotive and construction industries. It can withstand heavy loads and is resistant to corrosion, making it an ideal material for outdoor applications.

Another benefit of hot dip wire is its strength. The addition of other metals to zinc improves its durability and tensile strength, making it suitable for applications that require a sturdy material. This strength makes it useful for creating components in the automotive and construction industries. It can withstand heavy loads and is resistant to corrosion, making it an ideal material for outdoor applications.

Zinc alloy wire is also an excellent conductor of electricity. This property makes it suitable for use in electrical and electronic applications. The alloy can be used to create electrical wiring, connectors, and other components that require a high level of conductivity. The addition of other metals to the zinc also improves its thermal conductivity, making it suitable for use in heat exchangers and other applications that require efficient heat transfer.

In addition to its functional properties, hot dipped galvanized iron wire is also a popular material for decorative purposes. Its malleability and strength make it ideal for creating decorative pieces, such as picture frames, candle holders, and other home decor items. The alloy can also be plated with different metals, such as gold or silver, to give it a more luxurious look.

Overall, zinc alloy wire is a versatile material with many unique properties that make it suitable for a wide range of applications. Its malleability, strength, and conductivity make it a favorite among designers, engineers, and manufacturers. Whether it is used for construction, jewelry making, or decorative purposes, zinc alloy wire is a material that offers durability, functionality, and aesthetic appeal.

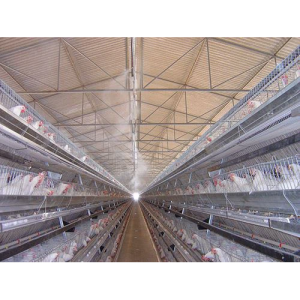

Hot Dipped Galvanized Iron Wire

Galvanized Wire is made to AS/NZS 4534 “Zinc and zinc/ aluminium-alloy Coatings on Steel Wire”; BS EN 10244. The metallic zinc coatings applied by the galvanizing process are an effective way of combating corrosion in steel. Galvanized wire for general manufacturing purposes is available in a standard galvanized coating or a heavy galvanized coating. Standard galvanized coatings are smoother, however less corrosion resistant than heavy galvanized coatings and are often used in normal wire working applications. Some typical end users include cages, bucket handles, coat hangers and baskets. Heavy galvanized coatings are used in conditions where atmospheric corrosion is severe. End users include crop support wires where chemicals are used, pool fencing or chain mesh in coastal areas.