Patented Steel Wire

Product information:

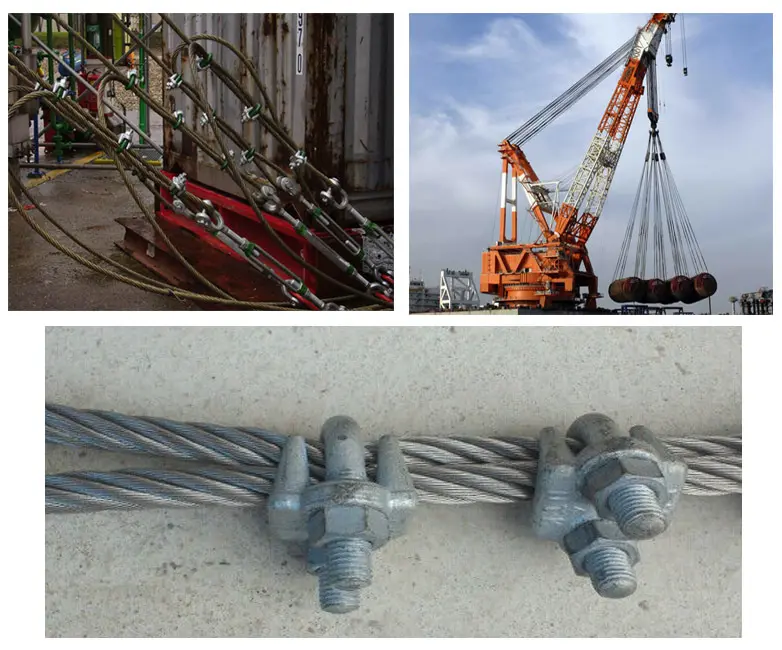

Patented Steel Wire has been cold drawn to the required diameter and heat treatment is available. Often it is used for redrawing for spring wires; redrawing for steel wire ropes; redrawing for flat shaped wires and optic cable strengthening. The phosphate process can remove the surface rust of steel wire. More importantly, it forms the phosphating film on the surface of steel wire, which can protecting the steel wire from rusting.

The strength and diameter can be customized.

Additional Info:

Diameter Range: 1.60-8.00 mm

Quality judgment:

1. Specific gravity. The diameter of the wire rope is the same, the heavier the specific gravity, the better the quality of the wire rope;

2. Steel wire rope core. The stronger the core of the wire rope, the heavier the specific gravity, the better the support for the outer strands of the wire rope, and the better the quality of the wire rope;

3. Materials. The material is the steel grade and strength. The higher the steel number, the better the quality of the wire rope with higher strength;

4. After the rope is cut, the slightly loose quality is good, and the quality of the wire rope with a relatively long lay length is better than that with a short lay length;

5. The anti-corrosion ability of 316 stainless steel wire rope is stronger than that of 306 stainless steel wire rope. The quality of plastic wire rope is better than that of PVC plastic coated wire rope, and the anti-corrosion ability of plastic coated wire rope is stronger than that of galvanized wire rope.

Diameter Properties:

| Nominal Wire Diameter | Tolerance (mm) |

| 1.60mm up to and incl. 1.80mm | +/- 0.02 |

| over 1.80mm up to an incl. 2.80mm | +/- 0.03 |

| over 2.80mm up to and incl. 5.00mm | +/- 0.03 |

| over 5.00mm up to and incl. 8.00mm | +/- 0.03 |

Tensile Strength (MPa):

The tensile strength is defined as the maximum load achieved in the tensile test, divided by the cross-sectional area of the wire test. The tensile strength developed depends on the amount of reduction in area to the finished size. Tensile is not considered of prime importance to this product however the following table is given as a general guide:

Technical Requirement:

| Name. | Diameter | Tensile Strength | Zinc Coating | Packing | Usage |

| (mm) | (Mpa) | (g/m2) | |||

| Galvanized redrawing wire | 2 | 950-1100 | min 200 | Coil | Process Wire for Wire rope |

| 2.2 | 980–1080 | min 220 | |||

| 2.5 | 1050-1100 | min 250 | |||

| 2.7 | 1170-1250 | min 280 | |||

| 3.2 | 1090-1190 | min 300 | |||

| Nongalvanized redrawing wire | 1.8 | 1000-1150 | None | ||

| 2 | 980-1250 | ||||

| 2.5 | 1175-1225 | ||||

| 3 | 1180-1300 | ||||

| 3.5 | 950-1150 | ||||

| 4.2 | 1050-1250 | ||||

| 5.5 | 950-1250 |

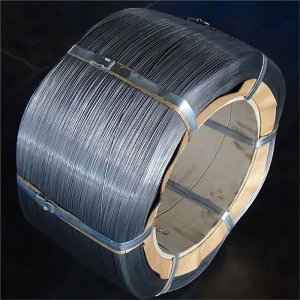

Packing:

Jumbo Coil Paking; ID 450mm OD 800mm; OR ID 508mm OD 840mm

Steel Chemistry

Raw Material: 45#, 55#, 60#, 70#, 72A, 80#, 82A

The table below is indicative only of steel chemistries used.

| - | HDLC | Truform | Hiform |

| % Carbon | 0.04 – 0.07 | 0.05 max | 0.06 max |

| % Phosphorus | 0.03 max | 0.03 max | 0.04 max |

| % Manganese | 0.40 – 0.60 | 0.50 max | 0.25 – 0.50 |

| % Silicon | 0.12 – 0.22 | 0.12 – 0.18 | 0.05 max |

| % Sulphur | 0.03 max | 0.03 max | 0.04 max |

Application: