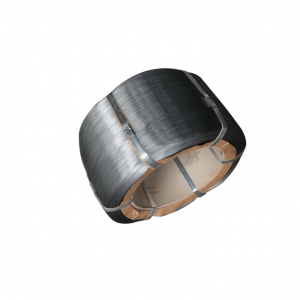

Phosphated Steel Wire For Automotive Seats

| Product Name | Phosphated Steel Wire | Place of origin | Tianjin, China |

| Brand | MJH | Use | Automotive Seats |

Hard Drawn Low Carbon Wire has been cold drawn to the required diameter and heat treatment is available. Often used for plating, redrawing and coating, it is important that the surface finish of the wire is clean and smooth. It will take moderate bending or flattening, machine ability is fair and the wire can be roll threaded.

This is a general purpose manufacturing wire suitable for a large range of applications. Various applications include super market trolleys, shelving, baskets, racks, hooks and general automotive parts.

Hard Drawn Low Carbon Wire Specifications

Diameter Properties

Hard Drawn Low Carbon Wire is manufactured to comply with the following diameter tolerances:

| Nominal Wire Diameter | Tolerance (mm) |

| 1.60mm up to and incl. 1.80mm | +/- 0.02 |

| over 1.80mm up to an incl. 2.80mm | +/- 0.03 |

| over 2.80mm up to and incl. 5.00mm | +/- 0.03 |

| over 5.00mm up to and incl. 8.00mm | +/- 0.03 |

Tensile Strength (MPa)

The tensile strength is defined as the maximum load achieved in the tensile test, divided by the cross-sectional area of the wire test. The tensile strength developed depends on the amount of reduction in area to the finished size. Tensile is not considered of prime importance to this product however the following table is given as a general guide:

| Nominal Wire Diameter | Tensile Range (Mpa) |

| less than or equal to 1.75mm | 800/1100 |

| over 1.75mm up to and incl. 2.00mm | 750/1050 |

| over 2.00mm up to and incl. 2.24mm | 700/1000 |

| over 2.24mm up to and incl. 2.70mm | 650/950 |

| over 2.70mm up to and incl. 2.80mm | 600/900 |

| over 2.80mm up to and incl. 4.20mm | 550/850 |

| over 4.20mm up to and incl. 10.00mm | 500/800 |

| over 10.00mm up to and incl. 11.50mm | 450/750 |

| over 11.50mm up to and incl. 12.50mm | 500/800 |

Steel Chemistry

Use a variety of steel grades to manufacture its Hard Drawn Low Carbon range. The table below is indicative only of steel chemistries used.

| - | HDLC | Truform | Hiform |

| % Carbon | 0.04 – 0.07 | 0.05 max | 0.06 max |

| % Phosphorus | 0.03 max | 0.03 max | 0.04 max |

| % Manganese | 0.40 – 0.60 | 0.50 max | 0.25 – 0.50 |

| % Silicon | 0.12 – 0.22 | 0.12 – 0.18 | 0.05 max |

| % Sulphur | 0.03 max | 0.03 max | 0.04 max |

Quality Control:

We use total quality control system. Every pieces of the raw material; semi-finished products and finished products are tested and recorded in file. The tracking record is used from final products to the very first beginning raw material steel factories.

Third Part like SGS is available for test control before shipment

Packing:

1) All the products are packed with seaworthy packing.

2) Customer’s special requirement for packing can be satisfied.

3) Air freight; sea freight and truck freight are all available.