Professional China High Carbon Steel Hot DIP Galvanized 2.4X3.0mm Oval Wire

With trustworthy excellent method, very good standing and excellent client provider, the series of items produced by our firm are exported to many countries and regions for Professional China High Carbon Steel Hot DIP Galvanized 2.4X3.0mm Oval Wire, All products appear with top quality and ideal after-sales solutions. Market-oriented and customer-oriented are what now we have been being following. Sincerely sit up for Win-Win cooperation !

With trustworthy excellent method, very good standing and excellent client provider, the series of items produced by our firm are exported to many countries and regions for China Oval Wire and Oval Galvanized Wire, Strong infrastructure is the want of any organization. We have been backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products and solutions worldwide. To maintain smooth work flow, we’ve sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

Product Information:

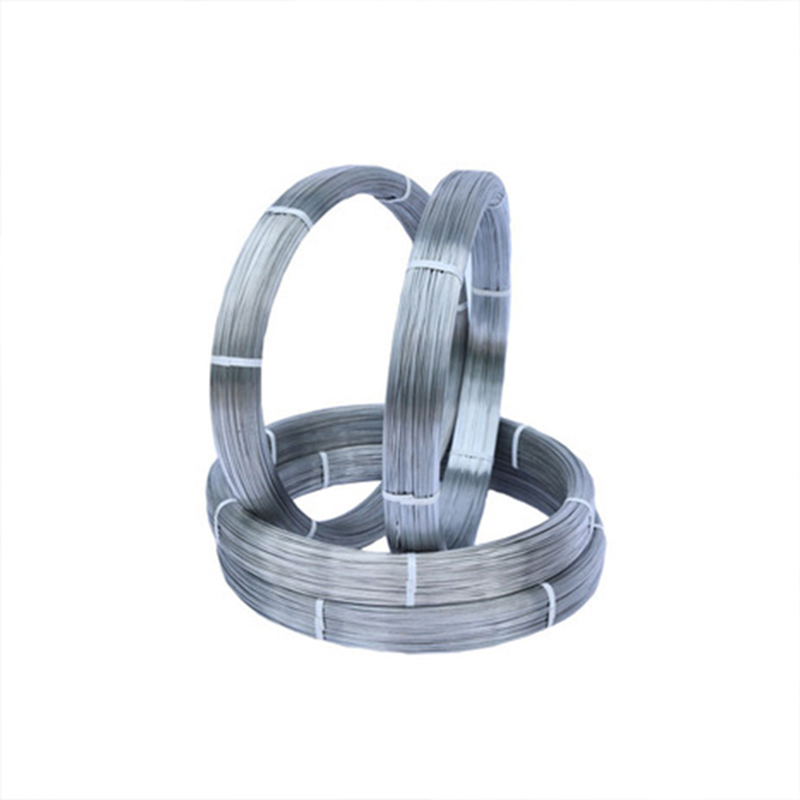

Galvanized Oval Wire as high tensile strength structures,which is corrosion, rust resistance, solid, durable and extremely versatile,widely used by landscapers, craft makers, building and constructions, ribbon manufacturers, jewelers and contractors. It is mainly as cattle fence wire to fence cattle farms in special place such as flooded lands,seashore farms, Ellipse, Agriculture, Fencing, Horticulture, Vineyard, Handicrafts, Trellis, and Horticulture structures, etc.

Galvanized Steel Oval Wire for cattle fence

Galvanised Wire Working Specifications

Given that galvanized wire is classified according to the amount of zinc coating, the following table outlines the difference between standard, heavy galvanized and extra-high galvanized wire.

| Nominal Diameter | Minimum Coating Mass (g/m2) | ||

| Standard Galv. | Heavy Galv. | Extra-highGalv. | |

| 2.4 mm * 3.00mm | 50 | 90 | 230 |

| 1.8 mm * 2.20mm | 50 | 90 | 230 |

| 2.0 mm * 2.4mm | 50 | 90 | 230 |

| 2.2 mm * 2.70mm | 50 | 90 | 230 |

| 4.45mm * 5.25mm | 35 | 50 | 230 |

Tensile Strength (Mpa)

The tensile strength is defined as the maximum load achieved in the tensile test, divided by the cross-sectional area of the wire test piece. Galvanized Wire is produced using soft, medium and hard grade wires. The following table specifies the tensile range according to the grade:

| Nominal Wire Diameter | Bread Loading (kgf) | ||

| Standard Galv. | Heavy Galv. | Extra-highGalv. | |

| 2.4 mm * 3.00mm | 600 | 800 | 870 |

| 1.8 mm * 2.20mm | 600 | 800 | 870 |

| 2.0 mm * 2.4mm | 600 | 800 | 870 |

| 2.2 mm * 2.70mm | 600 | 800 | 870 |

| 4.55mm * 5.25mm | 600 | 800 | 870 |

| Nominal Wire Diameter | Packing (meter) | ||

| 1 | 2 | 3 | |

| 2.4 mm * 3.00mm | 500 | 1000 | 1200 |

| 1.8 mm * 2.20mm | 500 | 1000 | 1200 |

| 2.0 mm * 2.4mm | 500 | 1000 | 1200 |

| 2.2 mm * 2.70mm | 500 | 1000 | 1200 |

| 4.55mm * 5.25mm | 500 | 1000 | 1200 |

Steel Chemistry

A combination of steel grades is used and heat treatment processes to manufacture soft, medium and hard tensile grades. The table below is indicative only of steel chemistries used.

| Tensile Grade | % Carbon | % Phosphorus | % Manganese | % Silicon | % Sulphur |

| Normal | 0.45~0.50 | 0.032 | 0.5 ~1.00 | 0.10~0.34 | 0.041 |

| High | 0.59~0.63 | 0.035 | 0.5 ~1.10 | 0.10~0.35 | 0.045 |

Feature:

Hot dipped galvanized oval wires are popular in livestock breeders.

They are easy to handle and corrosion & rust resistance to create the containment and protection fences in flat or regular regions.

Easy handling with oval section shape.

High tensile strength structures can withstand the impact from livestock and guarantee elastic effect on fence with maximum efficiency.

Production Process:

Step 1: Pass the steel wire through a pickling tank to remove oxides on its surface, and then wash it with water to remove the acid solution attached to the surface of the steel wire, and then dry the cleaning water attached to the surface of the steel wire.

Step 2: Pass the steel wire through a drawing machine. Pull to the required diameter of the finished product, and then make the drawn steel wire go through sandblasting treatment to remove the rust on the surface, and at the same time form a rough surface on the surface of the steel wire. When removing rust, it can form a certain rough surface on the surface of the steel wire, which makes it easier to absorb the galvanizing liquid when passing through the galvanizing tank, and then scrape off the excess galvanizing liquid through the fine holes, and cooperate with high-frequency heating to maintain the plating. The temperature of the zinc liquid makes it evenly distributed on the surface of the steel wire, so that the coating of the galvanized wire is formed more uniformly, and the overall performance of the galvanized wire is improved.

Packing:

1. Inner plastic cloth and outer woven bag. Woven bags of different sizes and colors.

2. Container or bulk ship loading.

3. According to customer requirements.

Details picture

Customize

Can be customized according to customer requirements.

Packaging

Various packaging forms, can be packaged according to customer needs

Quality

The product is of good quality, sturdy and durable, with a long service life

Application

With trustworthy excellent method, very good standing and excellent client provider, the series of items produced by our firm are exported to many countries and regions for Professional China High Carbon Steel Hot DIP Galvanized 2.4X3.0mm Oval Wire, All products appear with top quality and ideal after-sales solutions. Market-oriented and customer-oriented are what now we have been being following. Sincerely sit up for Win-Win cooperation !

Professional China China Oval Wire and Oval Galvanized Wire, Strong infrastructure is the want of any organization. We have been backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products and solutions worldwide. To maintain smooth work flow, we’ve sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.