Sealing Cars with Shaped Steel Wire

| Product Name | Steel Wire | Place of origin | Tianjin, China |

| Brand | MJH | Use | Sealing Cars |

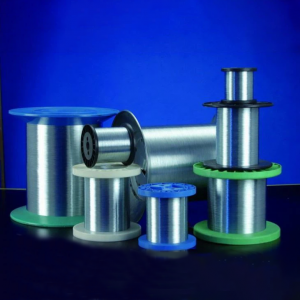

Shaped steel wire is the main raw material for the manufacture of sealed steel wire rope. It mainly refers to the non-circular cross-section steel wire, which is distinguished from the circular steel wire by name. The special-shaped steel wire is characterized by a complicated cross-sectional shape of the steel wire, high dimensional accuracy requirements, and a shape that satisfies special needs without further cutting. The production of profiled steel wire requires the use of special molds to process a variety of different shapes of steel wire by drawing, pulling and rolling. The process is relatively complicated and the production efficiency is relatively low.

Quality

Meet the requirements of “GB/T343 general purpose low carbon steel wire” and related standards.

Preparation

Wire raw materials Shaped steel wire is the main raw material for the manufacture of sealed steel wire rope. Its quality, performance and geometry directly affect the manufacturing quality and service life of the wire rope. The methods for producing the profiled steel wire include a cold rolling method, a roll die drawing method, and an integral die drawing method. The performance of the profiled wire depends to a large extent on the process of drawing deformation and the cross-sectional shape of the wire. Commonly used shaped wires have Z-shape, rail shape and trapezoidal shape; chevron and figure 8 are used less.

Tanning process The sealing of the sealing wire rope is divided into two steps. The first step is the tanning of the rope core, which is the same as that of the ordinary wire rope. The second step is to twist one or more layers of profiled wire on the finished core. The method of twisting the profiled wire layer is similar to that of a conventional wire rope, but requires a special splitter disk. A shaped groove with a certain slope in the disk. A profiled wire with asymmetrical cross-section must be ensured that one face (upper bottom) is always facing outwards, and each time a wire is passed, it is twisted 360 about its own axis. To obtain a smooth and good seal of the wire rope surface. For this reason, the special-shaped steel wire has a unique requirement from the shaft (winding) to the twisting, that is, the direction of the alignment should be selected (depending on the direction of the twist), and should be arranged neatly on the spool.

When sealing the inner layer of the steel wire rope, the lubricating oil should be applied as much as possible to facilitate the internal lubrication and anti-corrosion of the steel wire rope, but the surface of the steel wire rope should not be excessively oiled. The sealing wire rope should be made loose to increase its service life. The round wire rope used as the rope core has used the point contact steel wire rope in the past; the new structure of the steel wire rope has selected the wire contact wire rope of the round wire strand.