Steel Wire Rope

| Tensile Grade | % Carbon | % Phosphorus | % Manganese | % Silicon | % Sulphur |

| Standard | 0.45~0.50 | 0.032 | 0.5 ~1.00 | 0.10~0.34 | 0.041 |

| High | 0.59~0.63 | 0.035 | 0.5 ~1.10 | 0.10~0.35 | 0.045 |

| Extra-High | 0.65~0.83 | 0.035 | 0.5 ~1.10 | 0.10~0.35 | 0.045 |

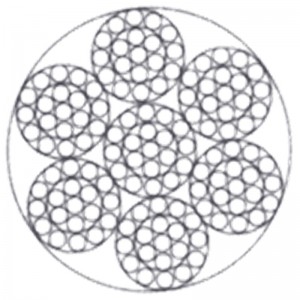

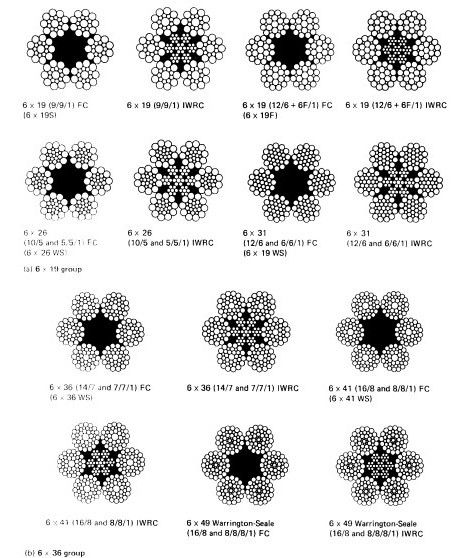

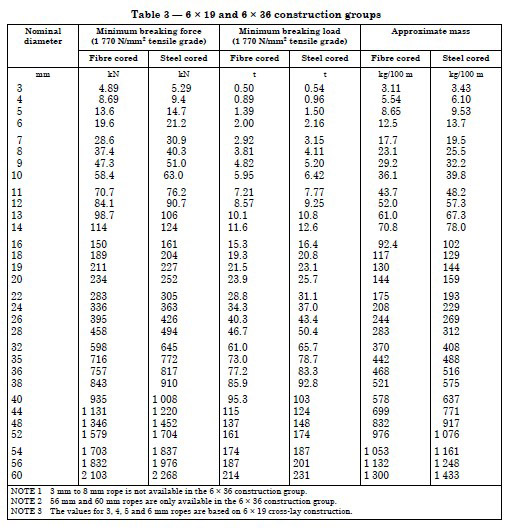

Steel wire rope is a spiral steel wire bundle that twists the steel wires with mechanical properties and geometric dimensions meeting the requirements together according to certain rules. It is composed of steel wire, rope core and grease. It has high strength, light self weight, stable operation, not easy to break the whole one suddenly, and reliable operation. It is a rope twisted into strands by multi-layer steel wires, and then twisted into a spiral shape by a certain number of strands with the rope core as the center. In material handling machinery, it is used for lifting, traction, tensioning and bearing.

Form:

Steel wire: steel wire rope needs to bear alternating load during use, and its service performance is mainly determined by steel wire mechanical properties, steel wire surface state and structure.

Rope core: the main function of the rope core is to support the steel wire rope to achieve a stable cross-sectional structure. The rope core includes steel core and fiber core. The fiber core includes natural fiber core and synthetic fiber core. The natural fiber core includes sisal, jute, cotton thread, etc., and the synthetic fiber core includes polyethylene and polypropylene filament, etc. The natural fiber core can store more grease, which can lubricate the steel wire rope and prolong the service life.

Grease: the grease is sprayed during the twisting process of steel wire rope, which has two main functions. One is to lubricate it and slow down the wear of the steel wire surface. The other is that the grease can isolate the steel wire surface from the oxygen in the air and inhibit the oxidation and corrosion of the rope.

Feature:

1. Steel wire ropes can transmit loads over long distances.

2. The bearing safety factor is large, and the use is safe and reliable.

3. Light weight, easy to carry and transport.

4. Can withstand a variety of loads and variable loads.

5. Has high tensile strength, fatigue strength and impact toughness.

6. Under high-speed working conditions, it has good wear resistance, shock resistance and good running stability.

7. It has good corrosion resistance and can work normally in harsh environments with various harmful media.

8. Good softness, suitable for traction, pulling, bundling and other purposes.

Process: The production of steel wire rope has three basic processes: drawing, twisting and closing.

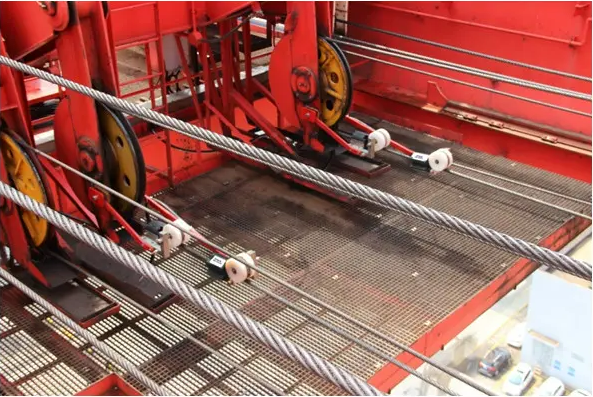

Application: inclined shaft lifting (winch), belt conveyer, ropeway, pulling of suspension bridge on the vessel (Steel Cored); Various equipment for elevating lifting and drawing, the rope with wire core can be use under the shock load, heated and squeezed conditions such as electric shovel, molten steel moving mechanism, etc.